- Home

- >

- Products

- >

- Hinge Bracket

- >

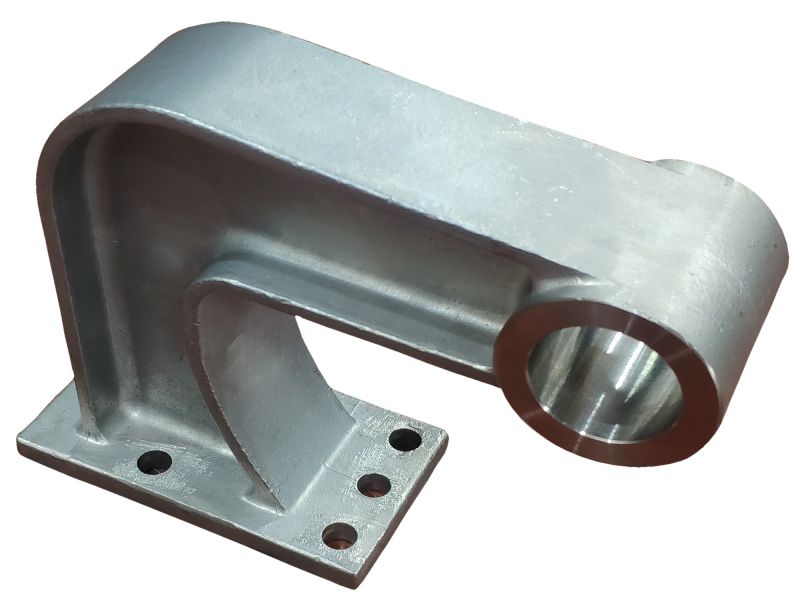

Hinge Bracket

1. Hinge Bracket has strong load-bearing capacity.

2. Hinge Bracket is durable and has a long service life.

3. The Hinge Bracket is well made.

- Information

Introduction of Hinge Bracket:

Hinge Bracket is a device that connects the front and the body of the train. Hinge Bracket, also known as hinge, is a mechanical device used to connect two solids and allow relative rotation between them. Hinges can be constructed of movable components, or of collapsible material.

Advantages of Hinge Bracket:

Hinge Bracket is made of optimal material, durable and long service life.

Hinge Bracket has excellent workmanship, high hardness, and is not easy to deform.

Hinge Bracket is carefully polished and trimmed, smooth and does not cut hands.

Hinge Bracket has a rigorous process and can be customized on demand.

Hinge bracket process introduction:

The advantage of sand casting is that due to the high dimensional accuracy and surface finish of investment castings, machining work can be reduced, only a small amount of machining allowance is left on parts with high requirements, and even some castings are only left for grinding, The polishing allowance can be used without machining.

In order to make sure that the product is in good condition when it reaches the customer's address, we strictly control the quality of the product and pack each product carefully, all in order to give the customer a better experience.

| MAIN PARTICULARS | |

| Heat treatment for mould | Hardened, HRC50~55 |

| Mould features | Advanced design, Logical structure, High precision, |

| Qualified materials, Long lifetime, Short delivery time. | |

| Material for product | gray iron/ductile Iron/alloy steel/carbon steel |

| Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Certificate | CE, ISO 9001:2015,RoHS,IATF16949:2016 |

| Tolerance | Up to +/- 0.002mm |

| Dimension | As per customers' request |

| Processing | Step1: Sand casting/Investment casting |

| Step2: CNC turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, drilling, wire-cutting, EDM, grinding etc. | |

| Step3: Surface treatment | |

| Surface | Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, etc. |

| Marking | as per clients' requirements |

| Inspection | material, dimension, heat treatment, hardness, NDT, surface |

| Quality | ISO9001/IATF16949 |

| Lead time | 20-30days for sample, consult with customer for mass production |

| Delivery | Express for sample, ocean shipping/air for mass production |

| Our Capabilities | CNC machining, CNC center machining, drilling, milling, turning, grinding, tapping, die casting, casting, forging, stamping,sand casting/investment casting |

| Engineering&manufacturing services | R&D process, tooling and gauging design, product design |

| Integrated CAD/CAM system, test and measuring | |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes /iron case or wooden boxes |

| As customer's specific requirements | |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Delivery method: FOB Dalian, either by sea or by air, according to the customer's specified requirements.

Delivery time: According to the size and content of the contract.

Terms of payment: T/T

Q:Are you a factory or trading company?

A: We are factory.

Q:What do I need for offering a quote?

A: Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

Q:How about the MOQ?

A:MOQ depends on your need ,besides, we welcome trial order before mass-production.

Q:Can I get a quote without drawings?

A:Yes, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q:How long can I have the sample

A:Depends on your products and request, it usually takes 7-20days.

Q:Will my drawings be divulged if you benefit?

A: No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q:Is it possible to know how is my product going on without visiting our company?

A:We will offer a detailed products schedule and send weekly reports with pictures and videos

Q: How do you control the quality?

A:Material inspection--Check the material surface and roughly dimension.

Production first inspection--To ensure the critical dimension in mass production.

Sampling inspection--Check the quality before sending to the warehouse.

Final inspection--100% inspected before shipment.

Q: What will you do if we receive defective parts?

A: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap