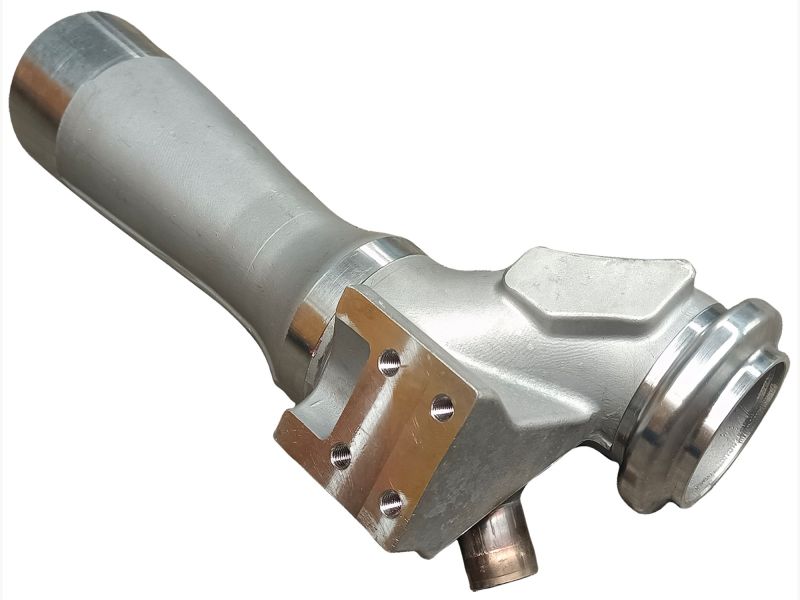

Excavator Exhaust Pipe

1. Excavator Exhaust Pipe is durable, made of high-strength materials, and has a longer service life.

2. Each exhaust pipe of Excavator steel casting has undergone precise manufacturing process to ensure the quality.

3. Excavator steel casting is made of high-quality materials, which is more durable.

- Information

Introduction of Excavator Exhaust Pipe:

Excavator Exhaust Pipe is cast with high-quality materials, which is durable and anti-corrosion, and can fully meet the needs of excavators for exhaust and heat dissipation during work. Excavator Exhaust Pipe adopts a streamlined design, which can effectively reduce air resistance and improve the working efficiency and performance of the excavator. We are committed to providing customers with high-quality products and services to make your work more efficient and safe.

Advantages of Excavator Exhaust Pipe:

High temperature resistance: Excavator steel casting can withstand high temperature and high pressure, making it safer to use.

Precise matching: Excavator steel casting perfectly matches the model of the excavator, so there is no need to worry about compatibility issues.

Easy replacement: Excavator steel casting can be replaced quickly without professional skills, saving time and cost.

Anti-sharp treatment: Anti-sharp, Excavator steel casting has a beautiful appearance and prolongs the service life.

High safety: Excavator steel casting complies with international safety standards, making it more reliable and safe to use.

What temperature can Excavator Exhaust Pipe reach:

The temperature of the Excavator Exhaust Pipe should be kept at about 100 to 120 degrees, and an increase in temperature will have an adverse effect on the machine.

The function of Excavator Exhaust Pipe is to release the deflagration exhaust gas from the exhaust port of the engine to reduce pollutant emissions.

| MAIN PARTICULARS | |

| Heat treatment for mould | Hardened, HRC50~55 |

| Mould features | Advanced design, Logical structure, High precision, |

| Qualified materials, Long lifetime, Short delivery time. | |

| Material for product | gray iron/ductile Iron/alloy steel/carbon steel |

| Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Certificate | CE, ISO 9001:2015,RoHS,IATF16949:2016 |

| Tolerance | Up to +/- 0.002mm |

| Dimension | As per customers' request |

| Processing | Step1: Sand casting/Investment casting |

| Step2: CNC turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, drilling, wire-cutting, EDM, grinding etc. | |

| Step3: Surface treatment | |

| Surface | Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, etc. |

| Marking | as per clients' requirements |

| Inspection | material, dimension, heat treatment, hardness, NDT, surface |

| Quality | ISO9001/IATF16949 |

| Lead time | 20-30days for sample, consult with customer for mass production |

| Delivery | Express for sample, ocean shipping/air for mass production |

| Our Capabilities | CNC machining, CNC center machining, drilling, milling, turning, grinding, tapping, die casting, casting, forging, stamping,sand casting/investment casting |

| Engineering&manufacturing services | R&D process, tooling and gauging design, product design |

| Integrated CAD/CAM system, test and measuring | |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes /iron case or wooden boxes |

| As customer's specific requirements | |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Quality Control:

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

We can supply products with follow test reports : |

1)Chemical composition report |

2)Tensile strength report |

3)Brinell hardness report,Rockwell hardness. |

4)Metallographic structure report |

5)Key dimension checking record report |

6)Full dimension report |

7)Third-party test report |

Q:Are you a factory or trading company?

A: We are factory.

Q:What do I need for offering a quote?

A: Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

Q:How about the MOQ?

A:MOQ depends on your need ,besides, we welcome trial order before mass-production.

Q:Can I get a quote without drawings?

A:Yes, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q:How long can I have the sample

A:Depends on your products and request, it usually takes 7-20days.

Q:Will my drawings be divulged if you benefit?

A: No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q:Is it possible to know how is my product going on without visiting our company?

A:We will offer a detailed products schedule and send weekly reports with pictures and videos

Q: How do you control the quality?

A:Material inspection--Check the material surface and roughly dimension.

Production first inspection--To ensure the critical dimension in mass production.

Sampling inspection--Check the quality before sending to the warehouse.

Final inspection--100% inspected before shipment.

Q: What will you do if we receive defective parts?

A: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap