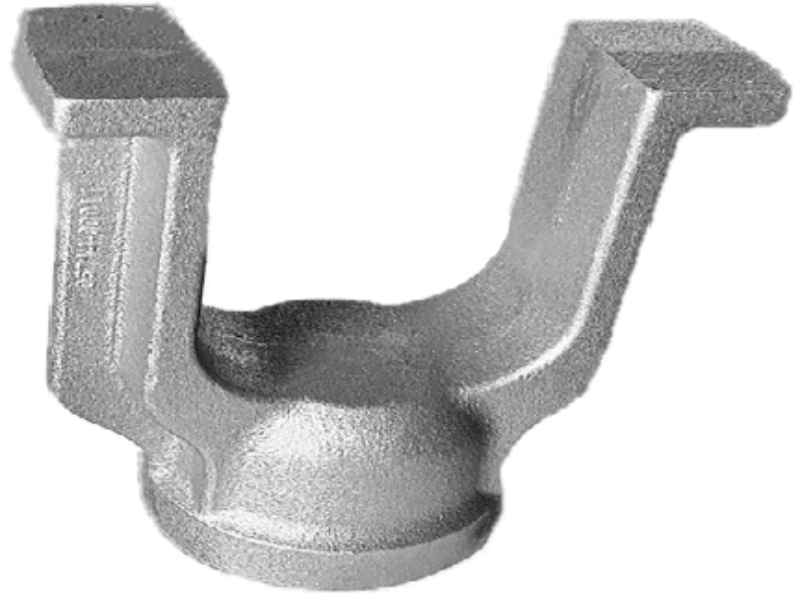

Agricultural Domestic Mini Excavator Sliding Yoke

1. The Agricultural Domestic Mini Excavator Sliding Yoke has high-quality construction and is durable.

2. Agricultural Domestic Mini Excavator Sliding Yoke has high dimensional accuracy.

3. Agricultural Domestic Mini Excavator Sliding Yoke is good for repair and maintenance.

- Information

Introduction of Domestic Mini Excavator Sliding Yoke:

The Agricultural Excavator Sliding Yoke is mainly to make the total length of the drive shaft expandable, so as to ensure that the relative position of the drive axle and the transmission is constantly changing without motion interference. The balance plate welded on the transmission shaft, in the manufacture of the transmission shaft, its mass distribution is often uneven, and it will vibrate when it rotates (especially at high speed), which will increase the extra weight of the intermediate bearing of the transmission shaft and the bearing of the drive gear of the reducer. load, accelerate bearing wear, and cause severe vibration of the car during driving. In order to eliminate this phenomenon, the method of adding welding balance sheet is used to make the balance reach the specified standard.

Key Features of Agricultural Domestic Mini Excavator Sliding Yoke:

1. The Agricultural Domestic Mini Excavator Sliding Yoke is designed to be easy to move in tight spaces.

2. Agricultural Domestic Mini Excavator Sliding Yoke has advanced technology, stable operation, safety and reliability.

3. Agricultural Excavator Sliding Yoke can better shape the forgings of transmission shaft sliding fork.

4. The structure of Agricultural Excavator Sliding Yoke is simple and reliable, and it is easy to disassemble during maintenance.

Specifications of Agricultural Domestic Mini Excavator Sliding Yoke:

| MAIN PARTICULARS | |

| Heat treatment for mould | Hardened, HRC50~55 |

| Mould features | Advanced design, Logical structure, High precision, |

| Qualified materials, Long lifetime, Short delivery time. | |

| Material for product | gray iron/ductile Iron/alloy steel/carbon steel |

| Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN |

| Certificate | CE, ISO 9001:2015,RoHS,IATF16949:2016 |

| Tolerance | Up to +/- 0.002mm |

| Dimension | As per customers' request |

| Processing | Step1: Sand casting/Investment casting |

| Step2: CNC turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, drilling, wire-cutting, EDM, grinding etc. | |

| Step3: Surface treatment | |

| Surface | Anodize, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving, ED- Coating, Chromate Plating, Zinc Plating, Dacromat Coating, etc. |

| Marking | as per clients' requirements |

| Inspection | material, dimension, heat treatment, hardness, NDT, surface |

| Quality | ISO9001/IATF16949 |

| Lead time | 20-30days for sample, consult with customer for mass production |

| Delivery | Express for sample, ocean shipping/air for mass production |

| Our Capabilities | CNC machining, CNC center machining, drilling, milling, turning, grinding, tapping, die casting, casting, forging, stamping,sand casting/investment casting |

| Engineering&manufacturing services | R&D process, tooling and gauging design, product design |

| Integrated CAD/CAM system, test and measuring | |

| Packing | Eco-friendly pp bag / EPE Foam /Carton boxes /iron case or wooden boxes |

| As customer's specific requirements | |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

Q:Are you a factory or trading company?

A: We are factory.

Q:What do I need for offering a quote?

A: Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and surface treatment information.

Q:How about the MOQ?

A:MOQ depends on your need ,besides, we welcome trial order before mass-production.

Q:Can I get a quote without drawings?

A:Yes, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q:How long can I have the sample

A:Depends on your products and request, it usually takes 7-20days.

Q:Will my drawings be divulged if you benefit?

A: No, we pay much attention to protect our customers' privacy of drawings, signing NDA is also accepted if need.

Q:Is it possible to know how is my product going on without visiting our company?

A:We will offer a detailed products schedule and send weekly reports with pictures and videos

Q: How do you control the quality?

A:Material inspection--Check the material surface and roughly dimension.

Production first inspection--To ensure the critical dimension in mass production.

Sampling inspection--Check the quality before sending to the warehouse.

Final inspection--100% inspected before shipment.

Q: What will you do if we receive defective parts?

A: Please kindly send us the pictures, our engineers will find the solutions and remake them for you asap

About our production technology:

Casting sizes from 1 to 3,500 pounds net shipping weight Green sand and no-bake automatic molding Solidification modeling CNC fully machining and CMM dimensional layout capability ISO 9001:2015 certification Complete oroduct testing and certification services State-of-the-art production -ray facility with radiographers on staff.